| CHECK VALVES |

|

REQUEST A QUOTE |

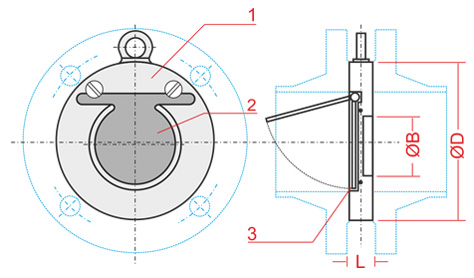

Wafer Check ValvesNormex, pioneers and Manufacturer, Supplier of unique Ball Check Valves, Ball Foot Valves, Hydrodynamic Guided NRVS have introduced yet another design of Non Return Valve Wafer check Valves. Normex wafer check valves are simple in construction have sturdy design & are reliable in operations. These valves are very useful where weight of the valve is required be low & there is a space constraint for valve fitment. The face to face distance in these valves is extremely less as compared to standard valves. |

| |

| |

| SIZES |

40mm to 600mm |

| PRESSURE RATING |

PN1.0/ PN1.6 (KPa) |

|

| |

| |

Salient Features

|

• Sturdy but simple design.

• 100% leak proof

• Short length - less space required.

• Light weight.

• Lower pressure drop across the valve.

• Low opening & closing pressures.

• Wide range of materials, temperature & pressure ratings

• Efficient flow characteristics.

• Can be mounted horizontally & vertically.

• Highly economical.

• Epoxy coating over the entire surface. |

| |

|

| |

| Part List / Materials of Construction |

| |

Part |

Standard Material |

Optional Material |

1. Body |

CI / MS |

CS, SS |

2. Disc |

SGI / MS |

SS |

3. 'O' ring |

Nitrile |

EPDM, Neoprene, Viton |

|

| |

| |

| Dimension Chart |

| |

Size |

≤ B |

≤ D |

L

(for Type WCV) |

mm |

in |

40 |

1.5 |

22 |

81 |

16 |

50 |

2 |

30 |

96 |

16 |

65 |

2.5 |

40 |

109 |

16 |

80 |

3 |

52 |

130 |

16 |

100 |

4 |

71 |

160 |

16 |

125 |

5 |

93 |

190 |

16 |

150 |

6 |

114 |

213 |

19 |

200 |

8 |

157 |

270 |

28 |

250 |

10 |

195 |

327 |

28 |

300 |

12 |

230 |

377 |

38 |

350 |

14 |

270 |

437 |

41 |

400 |

16 |

310 |

487 |

51 |

450 |

18 |

360 |

532 |

51 |

500 |

20 |

406 |

585 |

60 |

600 |

24 |

490 |

687 |

70 |

|

| |

| |

| Technical Data |

| |

Pressure Rating |

PN 1.0 & PN 1.6 (KPa) |

Types |

Without spring (WCV) & spring loaded (WSP) |

Sizes |

40mm to 600mm |

Temprature |

20*.C to 220'C |

Installation |

Horizontal /Vertical |

Flanges |

Between any standard flanges |

|

| |

| |

| Installation |

1) Normex Wafer Check valves can be installed between any two standard flanges.

2) The outside diameter of valve is designed considering the minimum P.C.D. available in various flange standards.

3) The valve should be centered between the outside diameter of the pipe flanges simultaneously while tightening the bolts.

4) Recheck that valve outside diameter is equidistant to flange diameter on all sides and fully tighten the bolts. |

| |

| |

|

|