|

| |

Butterfly Valves, Control Valves, Valve Manufacturer, Pune, India |

| |

| CONTROL VALVES |

|

REQUEST A QUOTE |

Butterfly ValvesThe control application in pumping systems attracted Normex to come out with control Valves i.e. Butterfly Valves. The Normex Butterfly Valve superseded the Gate Valve, Ball Valve and Globe Valve in most spheres of applications. Gas tight sealing with excellent control characteristics and uni directional flow has qualified Normex Valves by most of the industries. The centrally mounted disc, shafts and bearings has minimised head loss. It’s low weight and compact design has achieved acceptability in industries like Chemical and Petrochemicals, Watertreatment, Agriculture and many

• Excellent flow control in quarter turn operation

• Low pressure drop

• Low weight, low maintenance, long service life

• 100% tight shut of |

| |

| Salient Features |

- Excellent flow control in quarter turn operation.

- Compact, space saving design.

- Bi-directional1 00% tight shut off.

- Low weight, low maintenance, long service life, Easy automation / retrofit possible.

- Stream lined valve disc for lower pressure drop.

- Both shafts mounted in bearing supports for easy operating torques.

- Suitable for mounting between all standard flanges.

- Gasket packing not required to install between flanges.

- Sizes: 40mm to 400mm

|

| |

| Application |

1. Water treatment plants

2. Water distribution systems

3. Power Stations

4. Chemical / Petrochemical Industries

5. Steel Mills

6. Sugar Factories / Breweries

7. Sewage Plants

8. Process Industries

9. Seawater and Brine Pumping

10. Food Processing Industries

11. Mining Industries |

|

| |

| Parts list & Materials |

| |

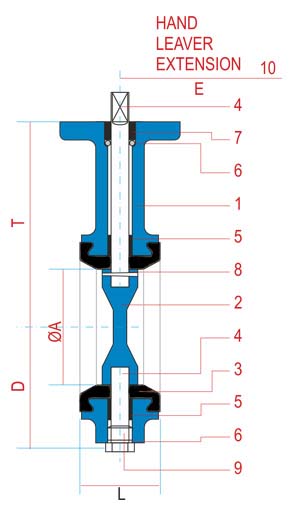

Part |

Description |

Std. mode of construction |

Options |

1 |

Body |

Cast Iron, GG - 25/ IS - 210 FG - 260/ BS - 1452 Gr. 260 |

SG Iron GGG 40 Cast Steel (WCB)

Stainless Steel CF8 / CF8M |

2 |

Disc |

SG Iron, GGG 40 IS - 1865 SG 400/12/ BS - 2789 Gr. 240/12 |

Cast Steel (WCB)

Stainless Steel CF8/CF8M

Aluminium Bronze IS 305 Gr2 |

3 |

Seat |

EPDM |

Black Nitrile, Neoprene, Viton, Silicon, Hypalon or as per customer's requirements. |

4 |

Shafts |

AISI 410 |

SS304/SS316 |

5 |

Bearings |

Self lubricating

Phosphor Bronze |

PTFE |

6 |

'O' Rings |

Nitrile |

EPDM, Neoprene |

7 |

Bush |

Polyacetal (Delrin) |

PTFE |

8 |

Taper Pin |

AISI 304/410 |

AISI 316 |

9 |

Plug |

Carbon Steel |

--- |

10 |

Hand Lever |

MS |

CI / SGI / SS |

|

| |

| |

| Dimension Chart |

| |

Size ( DN ) |

A |

L |

D |

T |

E |

Wt(Kg) |

40 |

33 |

55.5 |

101 |

240 |

2.1 |

50 |

43 |

64 |

111 |

240 |

2.8 |

65 |

46 |

72.5 |

121 |

240 |

3.4 |

80 |

46 |

79.5 |

128 |

240 |

3.6 |

100 |

52 |

99 |

147 |

240 |

4.6 |

125 |

56 |

115 |

159 |

240 |

6.3 |

150 |

56 |

128 |

173 |

330 |

8.7 |

200 |

60 |

156 |

199 |

330 |

12.2 |

250 |

68 |

212 |

248 |

500 |

25.0 |

300 |

78 |

239 |

270 |

- |

32.0 |

350 |

78 |

260 |

321 |

- |

64.5 |

400 |

100 |

298 |

345 |

|

69.4 |

450 |

108 |

326 |

373 |

- |

- |

|

| |

| Technical Data |

| |

|

PN 1.0 & PN 1.6 (KPa) |

Pressure Testing |

a) Body : 1.5 x PN

b) Seat : 1.1 x PN |

Temperature |

(-) 400C to 2000C |

Face to Face Dimension |

ISO - 5752 / IS - 13095/ BS - 5155 |

To suit flanges drilled as per |

IS, ANSI, BS, DIN Standards. |

Operation |

Bi-directional |

Painting |

Epoxy coated |

|

| |

|

| |

| Technical Comparison |

| |

| NORMEX BUTTERFLY VALVE & CONVENTIONAL GATE VALVE |

| Normex Butterfly Valve |

Conventional Gate Valve |

| Compact size, short in length saves space. Lower in weight. |

Bulky design, longer in length & higher in weight. |

| Can be used as On-Off as well partial opening or partial closing is possible. |

Can be used only as On-Off. Double flanged design. Flanges are required to be drilled for the specific standard. |

Flangless - fits between two flanges of any standards like IS, BS or ASA.

No drilling selection is required. Any valve off-the-shelf can be used for any drilling standards. |

Once drilled cannot be fit to other standard flanges. Hence off-the-shelf avalibility is poor. |

Quarter turn operation - valve opening to closing position is just quarter turn.

Hence on-off operation very easy. |

Multi turn operation - valve opening to closing requires at least 12 turns (depending on valve size) hence process is very tidious. |

| Any position of the valve viz, on, off or intermediate can be known visually. |

Valve position is not known especially in non rising spindle design. |

| 100% leakproof over the life. |

Leakproofness not guaranteed. |

| As it fits between two pipe flanges, only one set of bolts is enough for installation. |

Two set of bolts are required for installation - one set for each flange. |

| Lower priced - saves your cost. |

Higher price. |

|

| |

| |

|

|

| |

|