|

| |

Ball Type Check Valves, Normex Check Valves, Flap Type Return Valves, Manufacturer, Pune, India |

| |

| CHECK VALVES |

|

REQUEST A QUOTE |

| Principal:

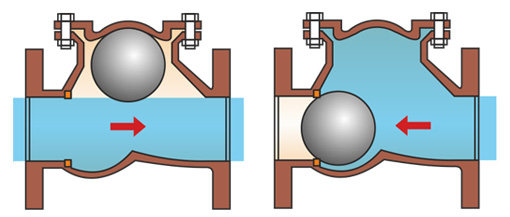

Ball Type Check Valves (NRV) B-01 was the first of the valve at Normex with unique design and technology for the first time in India. A very simple and robust design with no mechanism involved. The heart of valve is rubber coated ball. The mechanism hinge-pin-disc used in conventional check valves is eliminated and Normex has put in this rubber coated ball to arrest flow media in return condition.

As the pump starts, the ball moves out totally from the flow path when the pumping is on giving a full bore maximum flow/discharge with minimum head losses. (Fig. A). As the pump stops, the ball rolls back and seats perfectly on the rounded valves seat ensuring totally leak proof sealing.(Fig. B)

Salient Features:

- Lowest possible pressure drop across the valves.

- 100% leak proof sealing years over years.

- Non-clogging and self cleaning as ball rotates during operation.

- Virtually no wear and tear, no maintenance and longer service life.

- Higher solid handling capacity due to full bore and straight internal path.

- Lower head loss-high discharge, reduced pumping time-All leading to Energy Saving.

Applications:

Clean water, Raw water, Sewage, Slurry, Waste water, Viscous liquids etc.

Used in industries like:

Fire fighting, Plumbing, Water distribution, Water/Sewage treatment, Irrigation/agriculture, Sewage plants, Steel mills, Power stations,

Chemical/process industries, HVAC, Sugar/food industry, Breweries, Mining and many more. |

| |

|

|

| |

| DESCRIPTION |

STANDARD MATERIAL |

ON REQUEST |

| BODY/COVER |

CAST IRON (GG25) |

S.G.IRON(DI)/WCB/ST.STEEL |

| BALL |

NITRILE REINFORCED |

NEOPRENE/EPDM |

| SEAT RING |

L T BRONZE |

ST.STEEL |

| FASTENERS |

CARBON STEEL |

ST. STEEL |

| PAINT |

ENAMEL/EPOXY PAINT |

|

| END CONNECTION |

FLANGED |

|

|

| |

| |

| SIZE RANGE |

25mm TO 350mm |

| PRESSURE TESTING |

BODY: 1.5 X PN |

| |

SEAT : 1.1 X PN |

| |

|

| PRESSURE RATING - KPa |

|

| 25mm TO 125mm |

PN 1.6 |

| 150mm TO 300mm |

PN 1.0 |

| 350mm |

PN 0.6 |

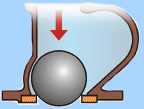

| INSTALLATION |

HORIZONTAL AS WELL AS VERTICAL |

| FACE TO FACE LENGTH |

IS 5312 PART I -1984/ DIN 3202-F6 |

| TEMPERATURE |

SUITABLE UPTO 800C |

|

| |

| |

• Dimensionally compatible with IS 5312 (Face to Face)

• Can be installed vertically or horizontally

• Operates silently

• Operates at temp 800C continuously (for 1000Capplication please contact us.) |

|

| |

| |

| Dimensions (A = Valve size in mm) |

| A |

25 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

350 |

| D |

115 |

150 |

165 |

185 |

200 |

220 |

250 |

285 |

340 |

395 |

482 |

527 |

| L |

144 |

174 |

200 |

240 |

260 |

300 |

350 |

400 |

500 |

600 |

700 |

800 |

| H |

115 |

160 |

180 |

210 |

230 |

280 |

340 |

400 |

500 |

570 |

680 |

800 |

| T |

15 |

15 |

16 |

16 |

19 |

20 |

21 |

21 |

22 |

24 |

25 |

29 |

|

|

| |

| |

| COMPARISON |

| |

| |

|

Normex Check Valve - Ball Type |

Conventional - Flap Type Return Valves |

1. Head Loss

(Pressure Drop) |

| |

|

| Low, Due to light, free

flowing rubber ball, without causing any interference, resulting in lower power consumption (frictionless) |

| |

|

| |

.gif) |

High, Due to interference of the heavy hinge/disc

mechanism, with the flow resulting in high power consumption. |

| |

|

| 2. Perfect Sealing |

| |

|

| The sealing face is deposit

free, since it remains inclined in any position of the valve, ensuring perfect sealing. (Drop less) |

| |

|

| |

.gif) |

Deposits on the sealing due to its flatness may not

ensure perfect sealing. |

| |

|

| 3. Solid Handling Capacity |

| Clear passage, equal to

nominal valve dia. gives larger solid handling capacity |

|

| The above interference leaves

a clear passage less than the normal valve dia., hence smaller solid handling capacity |

|

| 4. Self Cleaning |

| Any deposits formed on the

ball and in the valve passage are removed due to the rolling of the ball in operation. |

|

|

5. Non-Clogging

Nature |

| No moving parts other than the

free moving ball, hence no jamming/clogging. |

|

| Moving parts may jam due to

deposits. |

|

| 6. Applications |

| Unlimited. Ideal for slurries,

sewage, viscous, erosive & corrosive liquids. |

|

| Limited. Troublesome for

slurries, sewage & viscous liquids. |

|

| 7. Maintenance |

| Abrasion resistance of rubber

ensures longer life. Also the cleanout port does not necessitate valve removal from the pipeline. Hence much shorter downtime. |

|

| Parts may wear out due to

abrasion. Also, valve may be removed from the pipeline for maintenance/ cleaning. Hence longer down time. |

|

|

| |

|

|

|

| |

|